14/08/2024

What are Scissor-lift Tables?

Inkema scissor-lift tables improve the efficiency and safety of your facilities.

Scissor-lift tables are mechanical or hydraulic platforms designed to lift and lower loads safely and efficiently. They are essential in various industrial sectors to enhance logistics and workplace safety.

Types of Scissor-Lift Tables

Inkema divides its range of hydraulic tables into three types:

Single Scissor-Lift Tables

The table consists of a flat surface, a single scissor mechanism, and several hydraulic cylinders. Learn more about single scissor-lift tables.

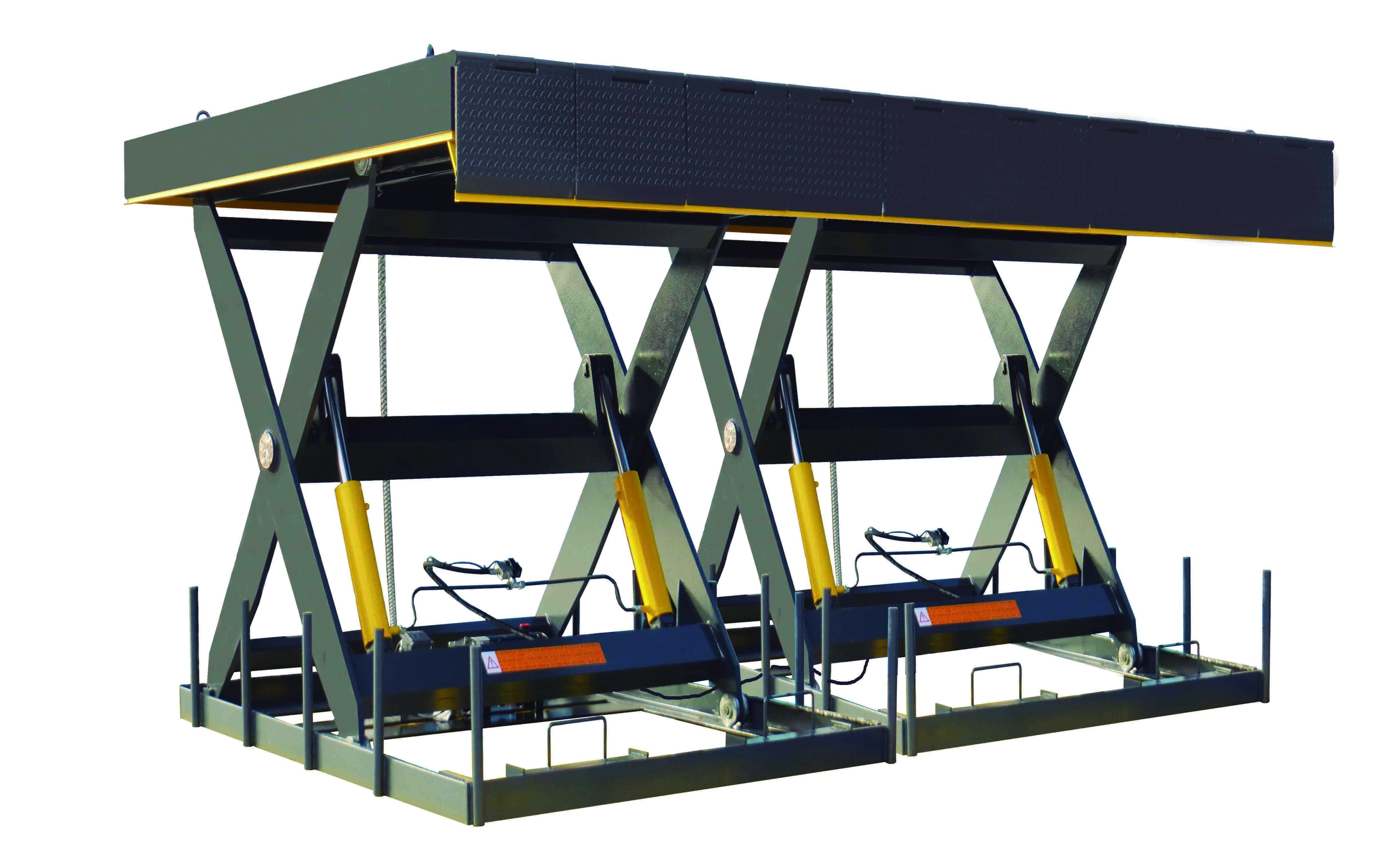

Double Scissor-Lift Tables

Designed for greater lifting height and/or larger load surfaces. They feature a platform, two scissor mechanisms, and several hydraulic cylinders. They come in 3 different types: vertical (MEX2), twin (MEX3), or tandem (MEX4). Discover more about double scissor-lift tables.

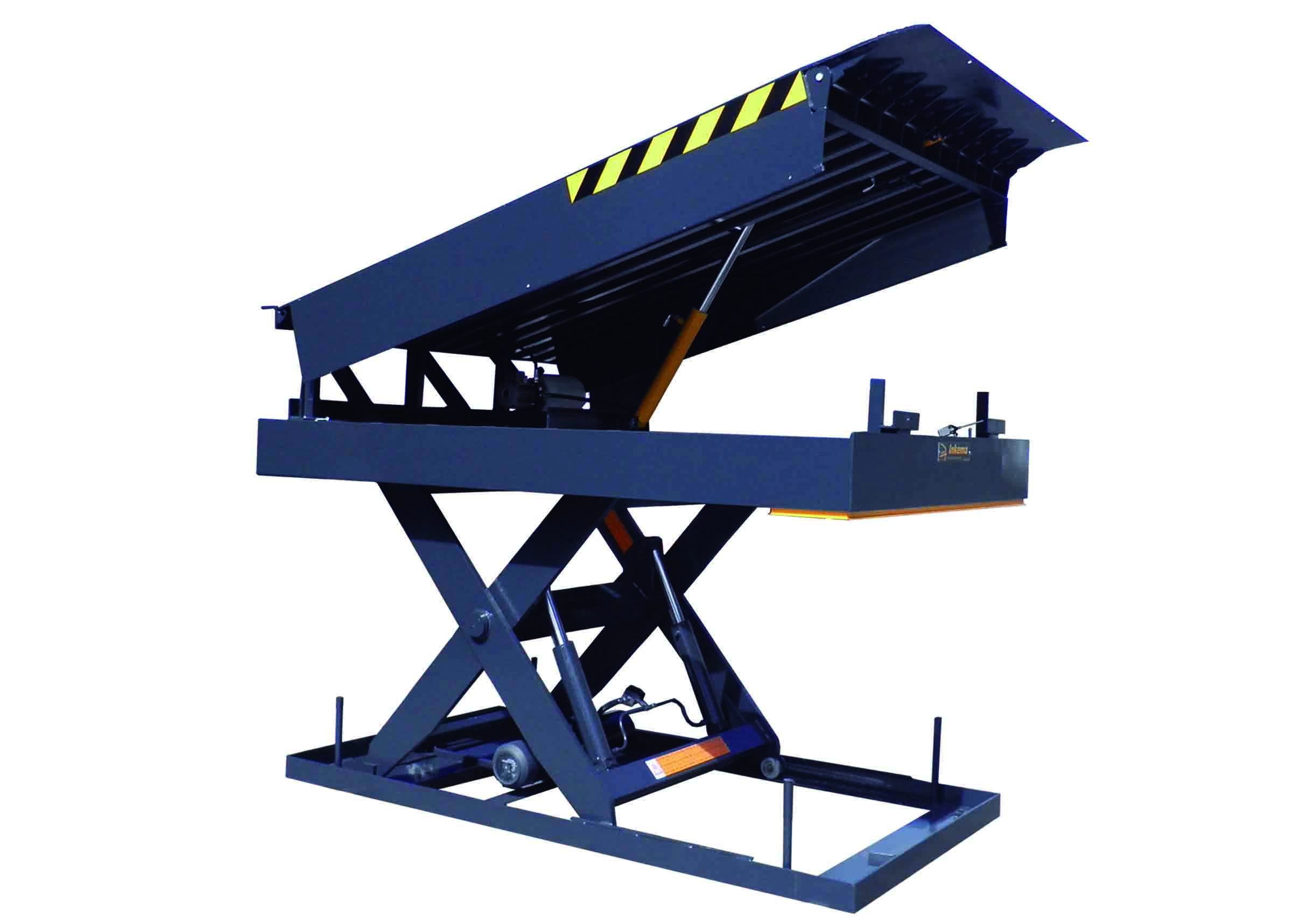

Dual SR Scissor-Lift Tables

A set of two machines in one. A hydraulic ramp with a foldable (SR) or retractable (SRB) lip is installed on a scissor-lift table. Learn more about Dual SR scissor-lift tables.

Advantages of Hydraulic Scissor-Lift Tables

⭐ Increased Efficiency

Scissor-lift tables allow for quicker and safer handling of loads, reducing the time and effort required to move materials.

⛑ Workplace Safety

Inkema scissor-lift tables are equipped with safety features such as railings, perimeter protection bellows, and locking systems that prevent falls and entrapments. By providing controlled and stable lifting of heavy loads, scissor-lift tables minimize the risk of injury and accidents for operators.

🧩 Versatility and Adaptability

Scissor-lift tables can be customized according to the specific needs of each client, making them extremely versatile in different industrial environments.

Applications of Scissor-Lift Tables

📦 Logistics and Storage

In warehouses and distribution centers, scissor-lift tables facilitate the loading and unloading of goods, optimizing workflow.

🏭 Production and Assembly

In production lines, these tables allow for adjustable working heights, improving ergonomics and operator efficiency.

🚗 Automotive Industry

In the automotive industry, scissor-lift tables are used for handling heavy and bulky components, enhancing efficiency and safety in the assembly process.

Inkema and Scissor-Lift Tables

Inkema has implemented hydraulic scissor-lift tables across various industries, improving the efficiency and safety of their operations. A notable example is the installation of scissor-lift tables in an automotive production plant, where they have significantly reduced component handling times. Read more about our success stories.

How to Choose the Right Scissor-Lift Table

Needs Assessment

Before selecting a scissor-lift table, it is crucial to assess the specific needs of your operation, including load capacity, lifting height, and frequency of use.

Safety Considerations

Ensure that the scissor-lift table meets all safety regulations and is equipped with additional safety features, such as railings and anti-fall locking systems. Inkema offers various safety systems as standard, which help reduce risks in your company's daily operations.

How a Scissor-Lift Table Works

Here is a brief video showing how a scissor-lift table works at a loading dock:

Request More Information

Scissor-lift tables are an indispensable tool in modern industry. Their ability to improve efficiency and safety in the workplace makes them a valuable investment for any company.