Product

Cold Storage System with Dock Leveller

Complete loading and unloading systems for the interior (PFIR) or exterior (PFER) of cold stores with high freight traffic.

There are two different Cold Storage System with Inkema telescopic leveller specially designed for the loading and unloading of goods, one for interior and the other one for the exterior of any installation where a high level of tightness is required.

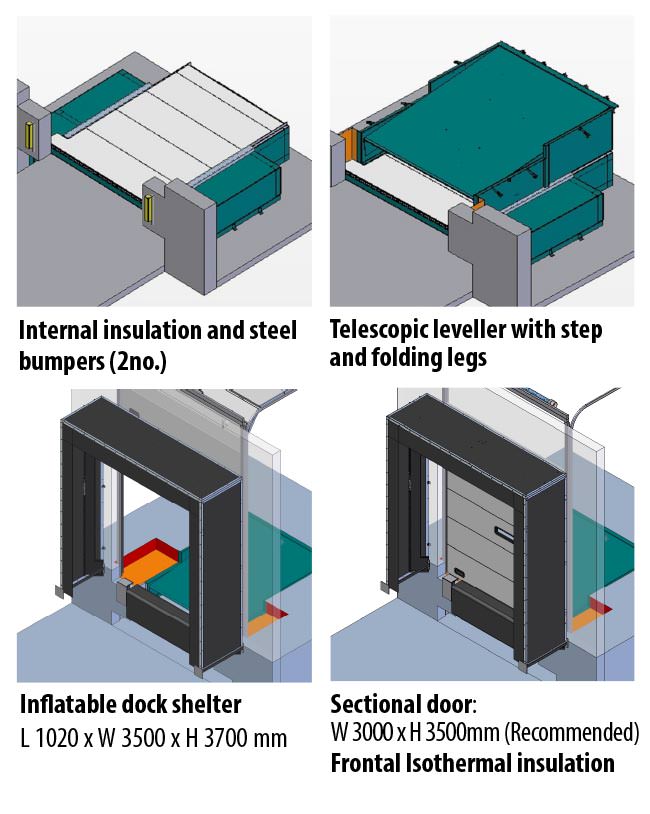

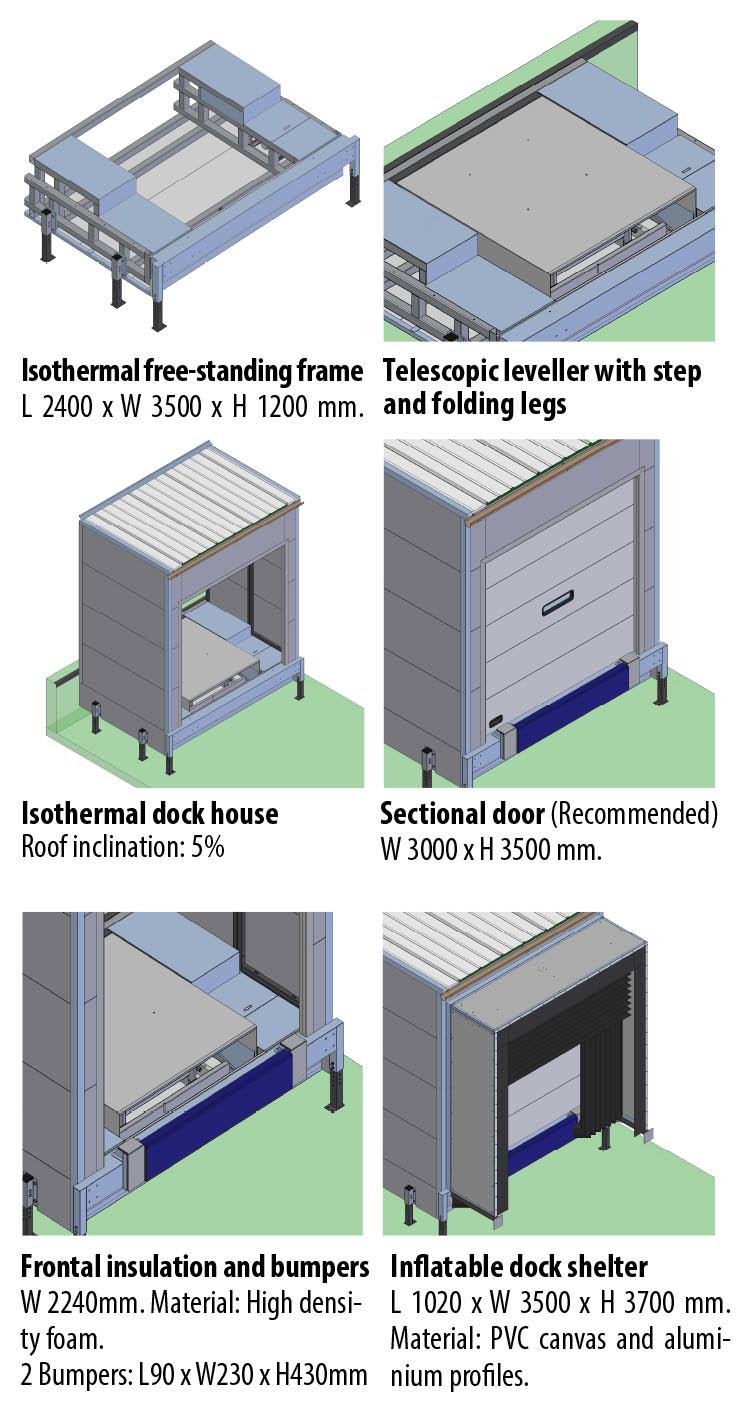

Both systems are formed by:

- a hydraulic leveller with telescopic lip

- inner frontal isothermal insulation

- steel bumpers

- an inflatable shelter

- an insulating sectional door

The only difference between both systems comes from the installation in external mode, which requires a free-standing frame and an isothermal dock house to act as an external loading bay.

COMPOSITION AS INTERNAL LOADING BAY - PFIR

OPERATION AS INDOOR LOADING BAY - PFIR

1. Once the truck is parked in the loading dock, the inflatable shelter begins to inflate until it is perfectly coupled to it. When the seal between the truck and the bay is optimal, the sectional door begins its opening until it is completely open.

2. Then, after opening the sectional door, we proceed now to open the rear gates of the truck that will be fitted onto the loading bay platform. When the truck gates are fully open, the hydraulic leveller will be activated and the loading and unloading process will begin. Thanks to the leveller’s telescopic lip, it fits perfectly to the platform of the truck allowing the transit between the building and the truck.

Once the loading or unloading is finished, the inverse process starts. The telescopic lip is withdrawn, and the leveller is lowered to its initial position. The gates of the truck are closed, followed by the sectional door. The shelter deflates and the truck can depart.

COMPOSITION AS OUTDOOR LOADING BAY - PFER

OPERATION AS OUTDOOR LOADING BAY - PFER

1. The truck parks in the loading bay, fitting perfectly to the inflatable shelter. Once the truck is blocked and sealed by the shelter, the doors of the system can be opened, as well as the truck gates.

2. Finally, when the truck doors are fully open, the hydraulic dock leveller is activated, to allow the loading and unloading process. Thanks to the leveller’s telescopic lip, it fits perfectly to the platform of the truck easing the transit between the building and the truck.

Once the loading or unloading is finished, the inverse operation process starts:

The telescopic lip is withdrawn, and the leveller is lowered to its initial position. The gates of the truck are closed, followed by the sectional door. Afterwards, the inflatable shelter begins to deflate and when it is totally collected into the sides of the dock house, the truck can depart